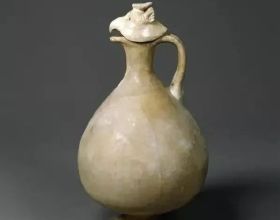

唐三彩(Tang Tri-Color Glazed Ceramics [1] ),中國古代陶瓷燒製工藝的珍品,全名唐代三彩釉陶器,是盛行於唐代的一種低溫釉陶器,釉彩有黃、綠、白、褐、藍、黑等色彩,而以黃、綠、白三色為主,所以人們習慣稱之為“唐三彩”。因唐三彩最早、最多出土於洛陽,亦有“洛陽唐三彩”之稱 。

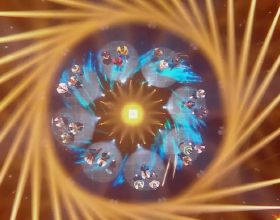

唐三彩轉心瓶

轉心瓶是中國陶瓷藝術的珍品。屬於清代創制的一種瓶式。在一個鏤孔瓶內,套裝一個可以轉動的內瓶,上繪各種紋樣。轉“轉心瓶”瓶體由內瓶、外瓶、底座分別燒製組成。

可以看到轉心瓶分為內外兩個主題,內部為轉心,底部圓柱面有著豐富的畫面,隨著角度不同在鏤空處展現的畫面也就不同,十分有趣,屬於十分高雅的觀賞器物。

唐三彩的製作工藝十分複雜。首先要將開採來的礦土經過挑選、舂搗、淘洗、沉澱、晾乾後,用模具作成胎入窯燒製。唐三彩的燒製採用的是二次燒成法。從原料上來看,它的胎體是用白色的粘土製成,在窯內經過1000-1100℃的素燒,將焙燒過的素胎經過冷卻,再施以配製好的各種釉料入窯釉燒,其燒成溫度約800℃。在釉色上,利用各種氧化金屬為呈色劑,經煅燒後呈現出各種色彩,此轉心瓶品相完美,釉色喜人,存世十分罕見,極具收藏價值。

英文翻譯:Tang Tri-color Glazed Ceramics [1], the treasures of ancient Chinese ceramic firing technology, full name Tang Tri-color Glazed pottery, is a kind of low-temperature Glazed pottery prevailing in the Tang Dynasty, glaze Color yellow, green, white, brown, blue, black and other colors, and yellow, green, white three-color mainly, So people used to call it "Tri-colored glazed pottery of tang Dynasty". Tri-colored glazed pottery of the Tang Dynasty is also known as "Luoyang Tri-colored glazed pottery of the Tang Dynasty" because it was the earliest and most unearthed in Luoyang.

Tang Tri-color revolving heart bottle

The revolving bottle is a treasure of Chinese ceramic art. It belongs to a bottle type created in qing Dynasty. Inside a carving bottle, a rotating inner bottle is set, with various patterns painted on it. The bottle body is composed of inner bottle, outer bottle and base respectively.

It can be seen that the revolving bottle is divided into two themes, inside the revolving center, the bottom cylinder has a rich picture, with different angles in the hollow out of the picture is different, very interesting, belongs to a very elegant ornamental objects.

The making technology of Tang Tri-glazed pottery is very complicated. First of all, the mining soil is selected, pounded, panning, precipitation, dry, with a mold into the kiln into the firing. Tri-glazed glazed pottery of the Tang Dynasty was fired by the secondary firing method. From the point of view of raw materials, its carcass is made of white clay, which is burned at 1000-1100℃ in the kiln. The roasted carcass is cooled, and then a variety of prepared glazes are applied into the kiln for glaze firing. The firing temperature is about 800℃. In the glaze color, using a variety of oxidized metal as color agent, after calcination presents a variety of colors, this rotating core bottle appearance is perfect, the glaze color pleasing, very rare, very valuable for collection.